Technology Forum of Delaware members learned about the world of 3D printing this week.

Joe Otto, owner of Sovereign Air, Newark, discussed the explosive potential of the process that has actually been around since the 1980s. The forum features monthly learning, social and competitive events. The event was held at the University of Delaware’s College of Health Sciences on the new STAR campus, the site of the former Chrysler plant.

In the past couple of years, the introduction of less expensive printers and the fascination of the media with the technology has put 3D printing on center stage, Otto said.

Otto says 3D printing is taking off, with improved software holding the key to even more explosive growth. Research indicates that only about 5 percent of companies and organizations that could use 3D printing are currently employing the technology.

Sovereign Air, Air is located in Pomeroy Plaza, off Main Street in Newark. The business does 3D printing in what Otto described as a “factory next the Ski Bum,” Otto told the group. The building once housed the Newark Post, which is now based in Elkton, Md. but operates on a “virtual” basis after cost cutting took place.

The business provides services that include prototypes of new products and even models of houses that can be used to test out paint colors.

While a few people see a day when 3D printers can produce household items, Otto says the reality is that such items are now too expensive.

He passed around a construction toy that would cost a customer $185, Otto said. That would not be a great deal on a toy, but shows the potential of using 3D printing to produce prototypes of toys or other items at a far lower cost.

Otto, who has a background in machine shop work produces parts for the aerospace industry, real estate and other areas.

Sovereign Air is also holding workshops and seminars on 3D printing. The potential for the technology is vast, especially as more off-the-shelf software is produced that can be used by smaller companies, Otto says.

Large companies, by contrast, produce proprietary software for their work, he noted.

The Tech Forum event also included a tour of the University of Delaware College of Health Sciences and its work in using 3D printing for custom research applications such as prosthetics.

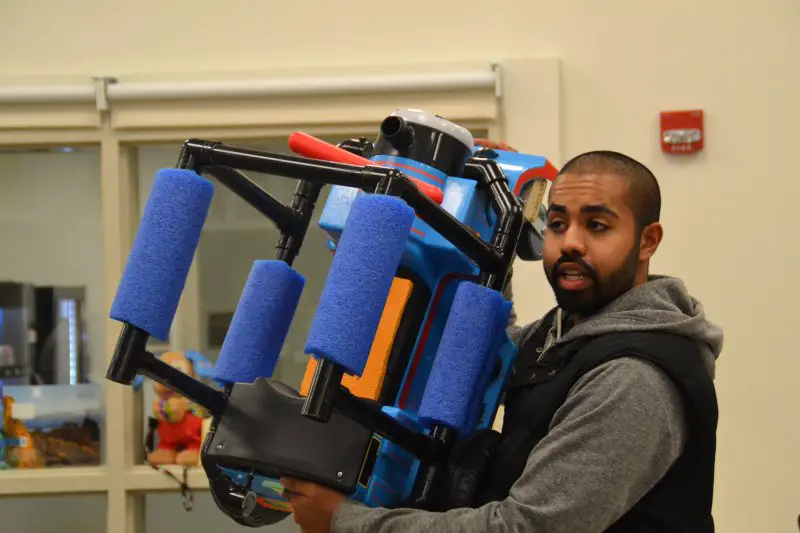

A unique program is GoBabyGo., which works to enhance mobility for children. 3D printing is used to provide mobility for young children who are growing too fast for wheelchairs. Off-the-shelf riding vehicles one finds at toy stores are refitted with 3D-printed components that combine mobility and fun.

Click here for more information about Tech Forum and its next event, an annual holiday party.